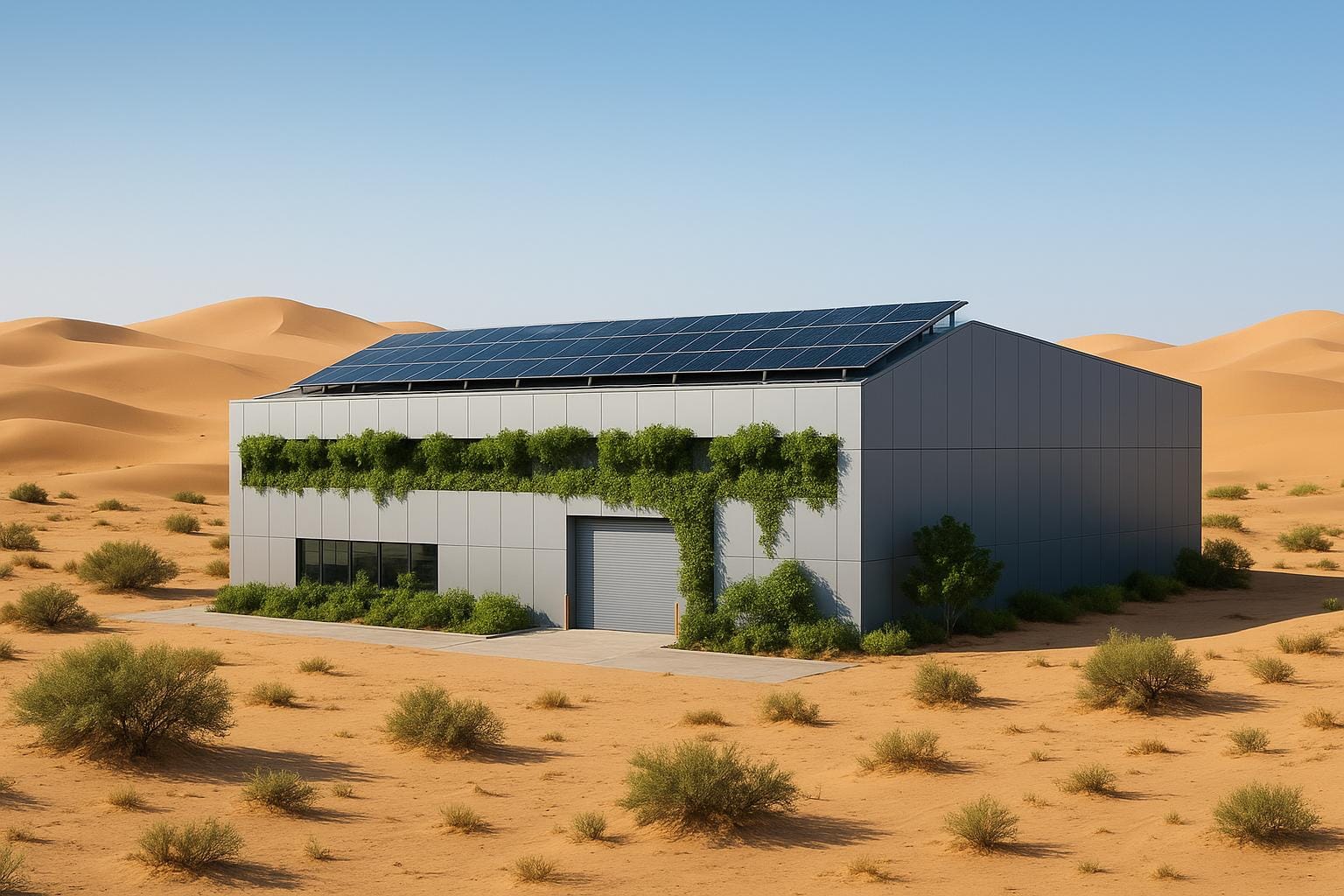

Green Warehousing: What Sustainability Looks Like in Arid Environments

Explore innovative green warehousing solutions tailored for arid climates, focusing on sustainability, energy efficiency, and water conservation.

Warehousing in desert climates faces unique challenges: extreme heat, scarce water, and high energy demands. But solutions like solar power, passive cooling, and water-saving systems are transforming these facilities into efficient, eco-conscious hubs. Here's what you need to know:

- Energy Efficiency: Solar panels, battery storage, and smart energy systems reduce electricity costs and ensure consistent power.

- Cooling Innovations: Advanced insulation, reflective roofs, and evaporative cooling lower indoor temperatures while cutting energy use.

- Water Management: Recycling systems and low-water landscaping address the region’s water scarcity.

- Climate-Specific Design: Dust-resistant materials, robust sealing, and thermal zoning protect goods and reduce maintenance costs.

- Digital Tools: IoT sensors and automated systems optimise operations and track sustainability metrics.

These strategies not only address operational hurdles but also align with regional goals like the UAE’s Green Building Council standards and Saudi Arabia’s Vision 2030. By tailoring solutions to local conditions, warehousing in arid climates is evolving to meet the demands of efficiency and resource conservation.

Energy Efficiency and Renewable Power

Energy costs are a significant concern for warehouses in arid climates. High temperatures, constant cooling needs, and around-the-clock operations drive up energy demand. However, these challenges also open doors to renewable energy solutions and improved efficiency.

Solar Power for Warehouses

The UAE, blessed with abundant sunlight year-round, is perfectly positioned to harness solar energy. This natural advantage is reshaping how warehouses manage their energy needs, with many facilities turning to solar power to cut down on traditional energy use.

Warehouses often feature expansive, flat roofs that are ideal for solar panel installations. These panels can meet a large portion of energy demands, with grid connections or battery systems stepping in during gaps. For facilities with extra land, ground-mounted solar arrays provide additional capacity, especially when fitted with tracking systems. These systems adjust the panels to follow the sun, maximising energy generation in the consistently sunny desert climate.

Battery storage has also become a practical option as technology has advanced and costs have dropped. Modern lithium-ion batteries store surplus energy generated during the day, making it available for use during peak evening hours. This not only reduces energy expenses but also ensures a steady power supply.

For warehouses looking to avoid upfront costs, Power Purchase Agreements (PPAs) are an attractive alternative. Through these agreements, operators can access solar power at competitive rates without needing to invest heavily in infrastructure. Maintenance responsibilities, too, are handled by specialised solar providers, making the process even more convenient.

Energy Management Systems and Smart Grids

While solar power is a game-changer, managing energy efficiently is equally important. Advanced energy management systems are revolutionising how warehouses track and control their energy use.

These systems combine real-time monitoring, automated controls, and predictive analytics to optimise energy consumption throughout the facility. Smart meters, for example, provide detailed insights into equipment-level energy use, helping identify areas where efficiency can be improved.

Demand response programmes offer another layer of savings by allowing warehouses to adjust their operations during peak electricity demand. Automated systems can dim lights, tweak temperatures, or reschedule non-essential tasks to lower costs and support the stability of the power grid.

Predictive maintenance tools also play a critical role. By analysing data like motor vibrations, temperature fluctuations, and power usage, these systems ensure equipment operates efficiently and maintenance is performed only when necessary, extending the lifespan of machinery.

Integration with smart grid infrastructure further enhances energy management. Warehouses can communicate directly with utility providers, feeding excess solar power back into the grid or drawing energy during off-peak hours when rates are lower.

Passive Cooling and Insulation

In addition to renewable energy and digital controls, passive cooling strategies can significantly cut energy use in warehouses.

In desert climates, passive design techniques can dramatically reduce cooling needs. These strategies rely on natural forces to maintain comfortable indoor temperatures with minimal mechanical intervention.

High-performance insulation is a key element of energy-efficient warehouse design. Modern insulation materials offer better thermal resistance than traditional options, reducing heat transfer through walls and roofs.

Reflective roofing materials are another effective solution. White membranes or reflective coatings deflect much of the sun's heat, easing the cooling load. Some advanced roofing systems even incorporate materials that moderate temperature fluctuations throughout the day.

Natural ventilation, using the thermal stack effect and prevailing winds, promotes air circulation during cooler times like early mornings or evenings. Strategically placed openings and shading devices make this approach even more effective.

Thermal mass techniques, which use dense materials like concrete or masonry, absorb heat during the day and release it at night, helping stabilise indoor temperatures. When paired with night ventilation, this method becomes even more efficient.

Evaporative cooling systems are particularly suited to the desert's low humidity. These systems cool air efficiently while consuming less energy. Indirect evaporative coolers are especially useful for maintaining ideal conditions in areas where humidity control is critical.

Lastly, well-placed windows with adjustable shades can optimise natural light while minimising heat gain. Automated blinds and louvers adjust throughout the day to balance sunlight and indoor lighting needs, cutting down on both cooling and lighting energy use.

Water Conservation and Management

Water scarcity poses a serious challenge in arid regions like the UAE and the broader MENA area. In such environments, managing water efficiently is critical - not just for operational needs like cooling, dust suppression, and maintenance - but also for maintaining surrounding landscapes. Adopting water-wise landscaping strategies can significantly reduce water usage at industrial facilities, aligning seamlessly with earlier energy efficiency measures. Together, these efforts are key to ensuring sustainable warehouse operations.

Low-Water Landscaping

Low-water landscaping relies on thoughtful plant choices and precision irrigation systems. For instance, native plants, naturally adapted to the local environment, require far less irrigation since they thrive on the region's limited rainfall.

Grouping plants with similar water needs into hydro-zones allows for targeted irrigation, cutting down on waste. Incorporating hardscaping elements - like permeable paving, decorative stones, and functional outdoor spaces - reduces the need for irrigated areas while also managing stormwater runoff more effectively.

Drip irrigation systems equipped with smart controllers take water conservation a step further by adjusting watering schedules in real time. Mulching is another practical technique; placing organic mulch around trees and shrubs can significantly decrease water loss through evaporation compared to leaving soil exposed.

Improving soil quality also plays a big role in water retention. Adding organic materials to the soil boosts its ability to hold water, helping plants grow stronger with less frequent watering. Additionally, strategically planting trees can create microclimates that improve overall efficiency. For example, deciduous trees on the south, east, and west sides provide shade during the summer, while evergreen trees on the north side act as windbreaks to minimise cooling losses.

These water-efficient methods align well with other digital and climate-adapted solutions in warehouse management, creating a more sustainable approach overall.

Climate-Adapted Design and Materials

Constructing warehouses in arid regions comes with its own set of challenges, including extreme heat, dust storms, and intense sunlight. To tackle these issues, innovative design and material choices are essential. Not only do they boost the durability of the facility, but they also help cut down on energy use and maintenance costs over time.

By combining energy-efficient strategies with climate-specific materials, warehouses can better withstand the harsh conditions of such environments. These approaches go beyond basic energy and water conservation, providing solutions to manage dust, heat, and temperature extremes effectively.

Climate-Friendly Construction Materials

Choosing the right materials is key to managing the challenges of arid climates. For instance, insulated concrete forms (ICFs) help stabilise internal temperatures, reducing the need for constant cooling.

Roofing materials also play a critical role. Reflective options, like cool roof coatings, are designed to lower roof surface temperatures during the hottest months. Examples include white thermoplastic polyolefin (TPO) membranes and modified bitumen with reflective granules, both of which are well-suited to these climates.

Walls can be designed for better thermal performance by using double-wall systems with continuous insulation. Precast concrete panels with integrated foam insulation not only improve temperature management but also provide protection against sandstorms and extreme temperature changes.

Locally sourced materials, such as limestone and regional aggregates, offer additional benefits. They reduce transportation costs, align with traditional building practices, and lower the overall carbon footprint of the construction process.

Dust and Heat Management Designs

Managing both dust and heat requires an integrated approach. For instance, positive pressure systems can help maintain clean airflow within the warehouse, preventing dust infiltration while regulating internal temperatures. Pairing these with airlock entry systems - double-door setups - creates an effective barrier against dust.

The building's orientation also matters. Aligning the structure along an east-west axis minimises sun exposure during peak hours, while placing loading docks on the north side reduces heat buildup during operations.

To further protect the facility, modern sealing techniques such as weatherstripping, structural glazing, and continuous vapour barriers create a tight building envelope. These measures reduce both dust intrusion and the loss of cooled air, paving the way for more efficient climate control inside.

Temperature-Controlled Logistics

When storing temperature-sensitive goods in extreme climates, precision is non-negotiable. Thermal zoning is one solution, dividing large warehouses into separate areas, each with its own climate controls tailored to specific needs.

Insulated dock doors and seals are vital for preventing temperature fluctuations during loading and unloading. High-speed roll-up doors with built-in insulation, combined with properly sealed dock openings, help maintain stable conditions.

Backup cooling systems and enhanced insulation ensure storage temperatures remain consistent, even during heatwaves. Automated systems equipped with real-time temperature monitoring can detect and address any deviations, rerouting products if necessary to maintain quality.

Humidity control is equally important in arid environments. Desiccant-based solutions effectively regulate indoor humidity, preventing issues like product degradation and condensation when goods move between different climate zones. These systems ensure that even in challenging conditions, products are stored safely and efficiently.

Digital Technology and Smart Warehousing

Digital technologies are reshaping green warehouse operations, especially in arid climates. These tools optimise energy use, monitor environmental conditions, and help facilities meet their sustainability goals, even in the face of harsh desert conditions.

Smart warehousing combines data from IoT sensors, smart meters, and automated alerts to deliver a real-time view of both operational and environmental performance. This is especially crucial in environments with extreme heat and dust, which can impact equipment and stored goods.

IoT and Warehouse Management Systems

IoT sensors play a central role in modern green warehouse management. These devices continuously monitor parameters like temperature, humidity, air quality, and energy use across different areas of a facility.

Environmental monitoring systems use wireless sensors to detect critical changes, enabling managers to address inefficiencies - like poorly cooled zones - before they escalate into higher energy costs. These sensors provide constant data, allowing for quick, informed adjustments.

Energy management gets a boost from smart meters, which track electricity use in real time. They can break down consumption by specific equipment or warehouse zones, helping identify and eliminate unnecessary energy use in vacant areas.

Warehouse management systems now go beyond traditional operations by incorporating sustainability metrics. These platforms provide dashboards that track carbon footprints, water usage, and waste generation, giving managers a holistic view of both operational efficiency and environmental impact.

This level of digital monitoring sets the stage for automation systems that further streamline warehouse operations.

Automation and Robotics

Automation and robotics bring efficiency to green warehousing by optimising energy use and reducing waste. For example, automated storage and retrieval systems eliminate the need for wide corridors designed for human workers, saving space and energy.

Automated cooling controls respond instantly to temperature changes. If sensors detect rising heat in a specific zone, the system reallocates cooling resources to that area, avoiding over-cooling elsewhere and ensuring optimal conditions where needed.

Robotic packaging systems minimise material waste by determining the exact packaging requirements for each product. These systems select the right box size and cushioning materials, cutting down on excess packaging and lowering transportation emissions.

Dark warehouse operations take efficiency a step further. These facilities operate with minimal lighting, using targeted illumination only when human intervention is required, such as for maintenance or quality checks.

Regulatory Compliance and Reporting

Digital tools also simplify compliance with regional environmental regulations. They compile and track data on energy, water, and emissions, ensuring facilities meet local standards with ease.

In the UAE, Green Building Regulations require large commercial facilities to report detailed energy consumption metrics. Digital systems automate this process by tracking key indicators like energy and water efficiency.

For companies operating across the GCC, monitoring carbon footprints is now essential. Digital platforms calculate emissions from electricity, transportation, and waste, providing accurate insights for compliance and sustainability efforts.

Real-time monitoring alerts managers when metrics approach regulatory limits. For instance, if water usage exceeds allowable levels or energy patterns suggest inefficiency, the system can trigger immediate corrective actions.

Audit trail features document every system change and decision, making regulatory inspections smoother and enabling continuous improvements. Integration with government platforms further streamlines compliance, allowing direct digital submission of required reports - an approach increasingly accepted across the GCC.

Regional Case Studies and Market Analysis

In regions where scorching heat and limited water resources are the norm, tailored innovations are proving essential. The GCC region, with its extreme climate and ambitious sustainability goals, has become a testing ground for forward-thinking warehouse models. Initiatives across the UAE, Saudi Arabia, and Qatar demonstrate how sustainable warehousing can address environmental challenges while keeping pace with shifting logistics demands. These examples are not just solving local problems - they’re influencing industry standards and shaping investment choices across the MENA region.

Case Study Comparisons

The development of green warehousing in the region highlights the importance of customised solutions. For example, the use of climate-resilient construction materials ensures stable indoor conditions despite the harsh external environment. These case studies emphasise the need to adapt strategies based on local resources and specific environmental challenges, offering practical insights for similar regions.

Market Trends in Green Warehousing

Regional insights reveal a significant shift in the approach to green warehousing. What started as experimental pilot projects is now becoming the norm, driven by government regulations, growing private investments, and tenant preferences for eco-certified facilities. This momentum is expected to lead to more large-scale warehouse developments that integrate sustainable technologies, setting a new benchmark for the industry in the region.

Conclusion: Key Insights for Green Warehousing

Green warehousing in arid regions has proven to be more than just an eco-friendly initiative - it’s a smart business move. The most successful approaches blend energy efficiency, water conservation, and climate-conscious designs tailored to desert conditions.

In the UAE and Saudi Arabia, solar power is a game-changer. With abundant sunlight, warehouses can harness this energy to reduce costs and achieve operational independence. Pairing solar systems with smart energy management tools further boosts efficiency and helps meet sustainability goals.

Water conservation is another critical component. Techniques like closed-loop cooling and greywater recycling not only address cooling demands but also minimise water usage. These methods align perfectly with climate-adapted designs, which strengthen the durability and efficiency of warehouse facilities.

Speaking of design, climate-adapted features - such as dust-resistant materials, better insulation, and passive cooling systems - are now essential for desert environments. These innovations cut down on maintenance expenses and improve energy efficiency over the facility’s lifespan.

Adding digital technologies takes things a step further. These tools turn static systems into dynamic, real-time resource management setups, ensuring optimal performance and conservation.

Lastly, regional customisation is key. Each area has its own challenges - what works for Qatar’s humid coast may not suit Saudi Arabia’s dry interior. Tailoring solutions, from materials to cooling systems, to fit local conditions is what makes green warehousing strategies truly effective in this part of the world.

FAQs

How do solar power and battery storage systems support sustainable warehouse operations in the UAE's arid climate?

Solar Power Systems for Warehouses in the UAE

Warehouses in the UAE are perfectly positioned to benefit from solar power systems, thanks to the region's abundant sunlight. By tapping into this clean and renewable energy source, businesses can cut down on their reliance on fossil fuels, significantly lower operational costs, and align with their environmental goals. Modern photovoltaic (PV) technologies are specifically engineered to thrive in desert climates, making them capable of withstanding intense heat and tough conditions.

To make solar energy even more effective, battery storage systems come into play. These systems store surplus energy generated during the day, ensuring it's available for use at night or during periods of high demand. Advanced options, like solid-state batteries, are particularly well-suited for the UAE's extreme temperatures. They offer greater safety, a longer lifespan, and consistent performance, even in challenging environments. Together, solar power and battery storage create a reliable and eco-conscious energy solution, ensuring uninterrupted operations while reducing environmental impact.

What are effective water conservation methods for warehouses in desert environments?

To tackle water scarcity in desert regions, warehouses can implement practical water-saving strategies. One approach is installing rainwater harvesting systems, which collect and store water for non-drinking purposes. These systems can cover up to 30% of a facility's water needs. Another effective measure is using water-efficient fixtures, such as low-flow toilets and sensor-activated taps, to cut down on unnecessary water use.

Warehouses can also benefit from green infrastructure solutions, like permeable surfaces and runoff management systems. These methods work by mimicking natural water retention processes, making them ideal for dry climates. Together, these strategies support sustainable operations while helping conserve vital water resources.

How can digital technologies and IoT sensors improve the sustainability and efficiency of warehouses in harsh climates like the UAE?

Digital technologies and IoT sensors are transforming how warehouses in extreme climates, like those in the UAE, operate. These tools enable real-time monitoring of environmental conditions, which helps fine-tune energy usage. For instance, cooling systems can run more efficiently, cutting down on energy waste - an essential advantage in the region's high temperatures.

On top of that, IoT solutions contribute to water conservation through automated irrigation and water management systems. This is a game-changer in arid climates, where water is a precious resource. By reducing resource consumption and improving operational resilience, these technologies help warehouses better handle the unique challenges of extreme environments.